5 Things you should know about using oil gauging tape measures

Oil gauging tape measures are an invaluable tool for anyone who needs to measure the depth of oil in storage tanks and other containers.

In this blog post, we’ll explain how to use oil gauging tapes, and answer some other common questions about this product.

HOW TO USE OIL GAUGING TAPE – INNAGE TAPE

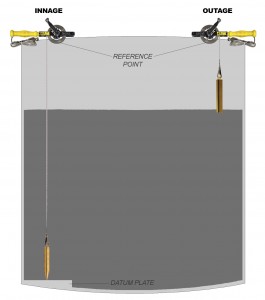

There are two techniques for manually measuring liquid levels in a tank: outage and innage.

Innage is the more common method and involves simply lowering the tape into a tank until the tip of the plumb bob reaches the bottom. When you reel in the tape, simply read the depth of the liquid in the tank by seeing where the tape is wet, similar to using a dip stick in a car.

HOW TO USE OIL GAUGING TAPE – OUTAGE TAPE

An outage tape measures the distance from the surface of a liquid in a tank to the top of the tank. In other words, the part of the tank without liquid.

It’s difficult to determine where the top of the liquid actually begins, so the graduated plumb bob is slowly lowered from the reference point just until it reaches the liquid.

The graduations on the bob begin where the bob is attached to the tape and get higher. The reading on the bob – as shown by the liquid – is added to the reading on the tape to determine the total empty portion of the tank.

When you know the depth of the tank, you can subtract the space that isn’t filled from the total depth to figure out the depth of the liquid. You can conclude the volume of the tank by multiplying depth times surface area.

This type of oil gauging tape is good for thick or caustic materials because the tape doesn’t go into the liquid.

HOW ACCURATE ARE THESE TAPES?

All of our oil gauging tapes meet both Mil Spec. # A-A-52216 and American Petroleum Institute Standard 2545. Both of these standards deal with the method for determining the accuracy of a tank gauging tape and the acceptable deviation.

USING DOUBLE DUTY TAPE

Double duty oil gauge tapes allow you to get measurements when working with both light and dark liquids. The tape has a black line along one edge allowing you to see light-colored fluids.

WHAT KINDS OF LIQUIDS CAN BE GAUGED?

Oil gauging tapes are plated with chrome nickel and are also double coated with two different lacquers. Using these tapes with gasoline, fuel oil, crude oil and other petroleum products should not remove the tape’s protective coating.

However, more exotic chemicals, acids, bases or a mix of chemicals can affect the outer lacquer. Abrasive materials such as sand can also shorten the life of the coating. Storing the tape blade in wet environments or neglecting to clean substances from the blade can also cause damage.

Using etched stainless-steel blades can help you avoid abrasive damage. These tape blades have no coating, with numbers and grad lines etched directly into the metal, making them less likely to be worn away by abrasives.

Although not as strong as a carbon-plated blade, a stainless-steel tape will hold up better in a caustic or wet environment.

If you have additional questions about oil gauging tapes, U.S. Tape would be happy to answer them. Contact us today.